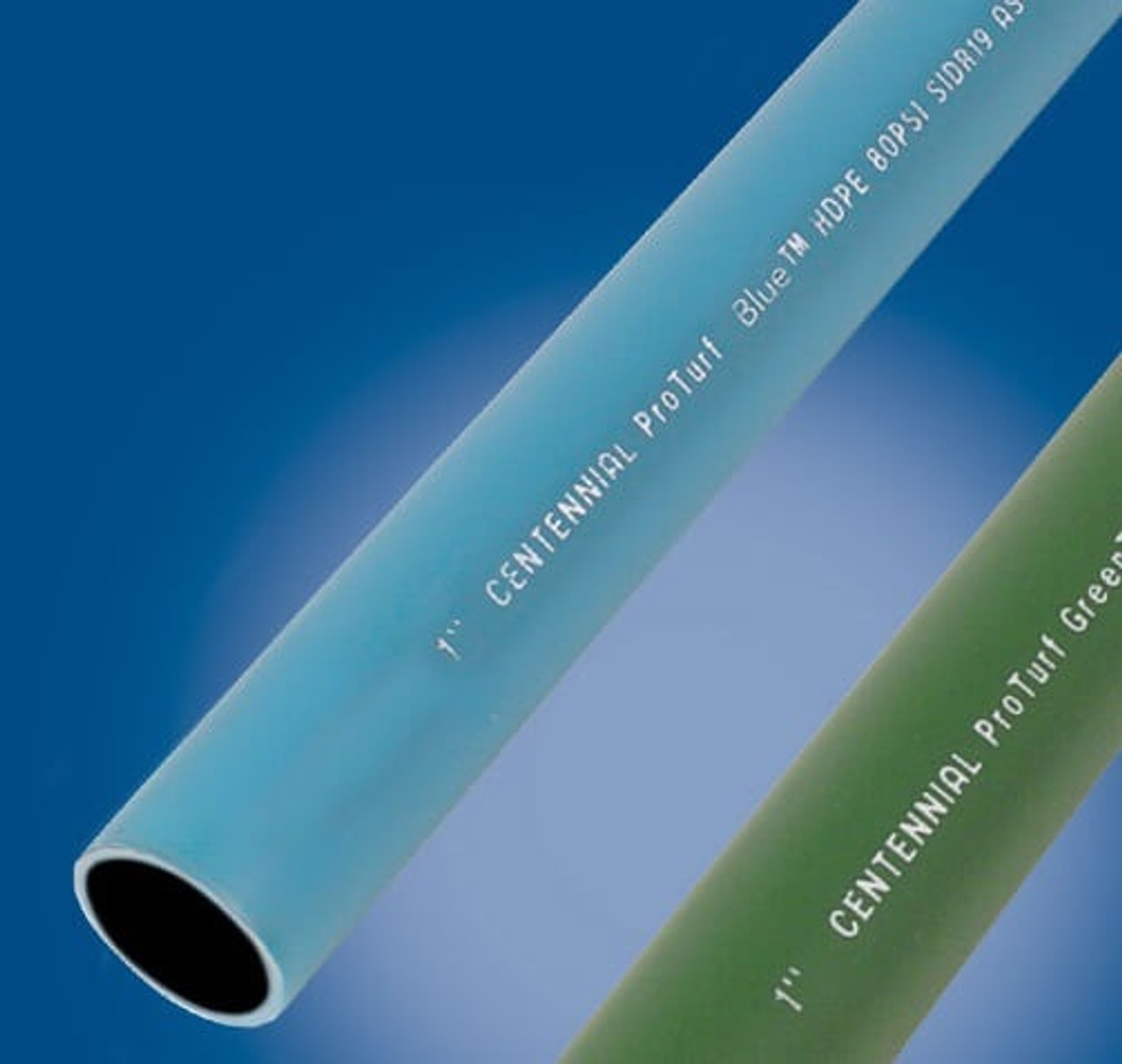

Common Questions About Texas hdpe pipe manufacturer and What They Offer

Comprehending the Trick Advantages of HDPE Pipeline for Water and Wastewater Monitoring

Using HDPE pipe in water and wastewater management provides numerous advantages that merit consideration. Its outstanding longevity and long lifespan make it a recommended choice for many projects. Additionally, the product's resistance to rust and chemical damages enhances its reliability in different atmospheres. The advantages expand beyond just longevity and resistance. custom hdpe pipe manufacturing Midland TX. Discovering its cost-effectiveness and environmental impact discloses also a lot more compelling reasons for its extensive adoption in modern framework

Remarkable Sturdiness and Long Life

HDPE pipeline stands apart for its phenomenal resilience and longevity, making it a recommended option in water administration systems. Created from high-density polyethylene, these pipelines can withstand substantial stress and anxiety, making sure reputable efficiency over time. Their robust nature enables them to withstand severe environmental conditions, including temperature level fluctuations and dirt activities, which can trigger various other materials to fall short.

The lifespan of HDPE pipelines usually exceeds 50 years, supplying an affordable service for towns and markets alike. Additionally, the material's light-weight residential properties streamline installation, reducing labor prices and timeframes. This resilience minimizes the demand for constant fixings or replacements, additionally improving its financial appeal.

In water administration applications, the integrity of HDPE pipes indicates fewer disruptions and boosted solution connection, making them indispensable to lasting framework advancement. The mix of resilience and longevity strengthens HDPE's role as a foundation in reliable water management services.

Resistance to Rust and Chemical Damage

While many materials succumb to corrosion and chemical damages gradually, HDPE pipes display remarkable resistance, making them optimal for various water management applications. This strength comes from the molecular framework of high-density polyethylene, which is inherently non-reactive and does not wear away like steels or break down from exposure to extreme chemicals. As an outcome, HDPE is highly effective in environments with aggressive substances, such as wastewater systems that may contain acids, bases, and organic solvents.

Furthermore, HDPE pipelines can hold up against environmental elements such as soil level of acidity and saline problems, further improving their suitability for varied applications (Midland TX HDPE Pipe Fittings in Stock). Their capacity to keep structural integrity in time reduces the risk of leakages and failings, which is crucial in making certain the safety and security and integrity of water circulation and wastewater management systems. The resistance to deterioration and chemical damage considerably contributes to the total performance and long life of HDPE piping remedies.

Cost-Effectiveness and Financial Benefits

When thinking about the economic ramifications of water monitoring systems, the cost-effectiveness of HDPE pipelines comes to be apparent. These pipes offer lower installation and maintenance costs compared to typical materials like steel or concrete. Their light-weight nature streamlines transport and installation, causing lowered labor costs. Additionally, HDPE pipelines show a lengthy life expectancy, commonly going beyond half a century, which converts to fewer substitutes and long-lasting financial savings.

The resistance of HDPE to rust and chemical damage lessens the need for costly repair services and substitutes. The pipelines also sustain reliable water circulation, decreasing power prices related to pumping systems. By mitigating leaks and water loss, HDPE pipes add to substantial economic advantages for towns and industries alike. Generally, the preliminary investment in HDPE piping can produce significant economic Going Here returns over the lifespan of the water monitoring system, making it a prudent selection for sustainable framework development.

Ecological Sustainability and Lowered Effect

Convenience and Flexibility in Installation

As a result of their unique buildings, HDPE pipes offer remarkable adaptability and adaptability in installation, making them suitable for a variety of applications. Their light-weight nature enables easier handling and transportation, minimizing labor find out here prices and installation time. HDPE pipelines can be curved and shaped to fit numerous terrains and project requirements, which is specifically beneficial in testing settings.

In addition, their resistance to rust and chemical damages permits installation in diverse settings without the need for specialized protective coatings. The capability to fuse joints develops a constant, leak-free system, boosting the total honesty and integrity of the setup. HDPE's flexibility also suits ground movement, lowering the threat of damage in areas vulnerable to changing dirt. On the whole, these characteristics make HDPE pipes not just Resources versatile yet additionally a recommended choice for water and wastewater monitoring systems.

Frequently Asked Questions

Exactly How Does HDPE Pipeline Contrast to PVC in Water Monitoring Applications?

HDPE pipe supplies remarkable flexibility, resistance to rust, and toughness compared to PVC. Its lighter weight assists in much easier setup, while its lengthy lifespan decreases replacement expenses, making HDPE a recommended option in water administration applications.

What Is the Lifespan of HDPE Piping Under Normal Problems?

Under normal problems, HDPE pipelines can have a life expectancy ranging from 50 to 100 years. Their toughness and resistance to deterioration add to their long-term performance in various applications, making them a reliable choice for framework.

Are HDPE Piping Recyclable After Their Life Span?

Yes, HDPE pipes are recyclable after their solution life. Pipe Supplier American Plastics Midland. They can be refined and repurposed into new items, significantly minimizing ecological impact and promoting sustainability within the industry, making them an environmentally friendly selection for piping solutions

What Is the Installment Refine for HDPE Piping?

The installation process for HDPE pipes includes site preparation, trenching, pipeline combination or mechanical signing up with, backfilling, and stress testing. Correct methods ensure a resilient and effective system for moving water and wastewater successfully.

Can HDPE Pipeline Be Utilized for Both Potable and Non-Potable Water Equipments?

Yes, HDPE pipelines can be used for both drinkable and non-potable water supply. Their adaptability, sturdiness, and resistance to deterioration make them suitable for numerous applications, ensuring secure and effective transportation of water in various contexts.